Turbine power generation system

KOREA GREEN ENERGY TECHNOLOGY

-

What's a Turbine power generation system?

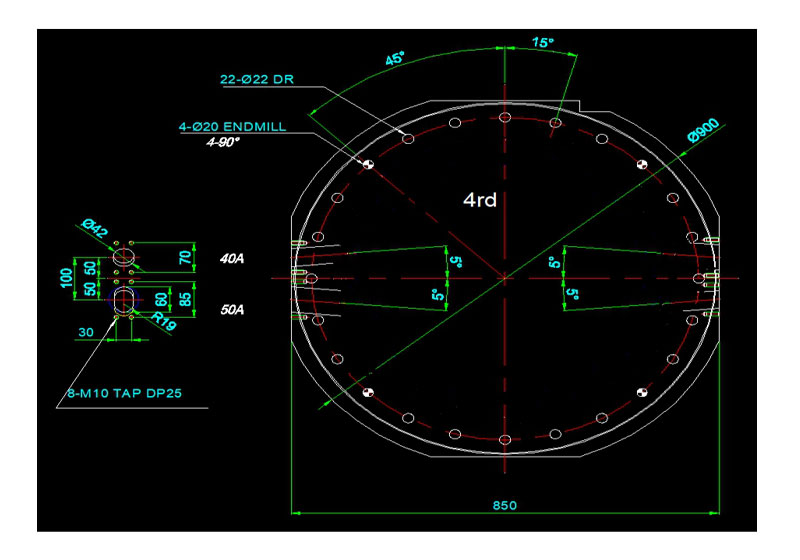

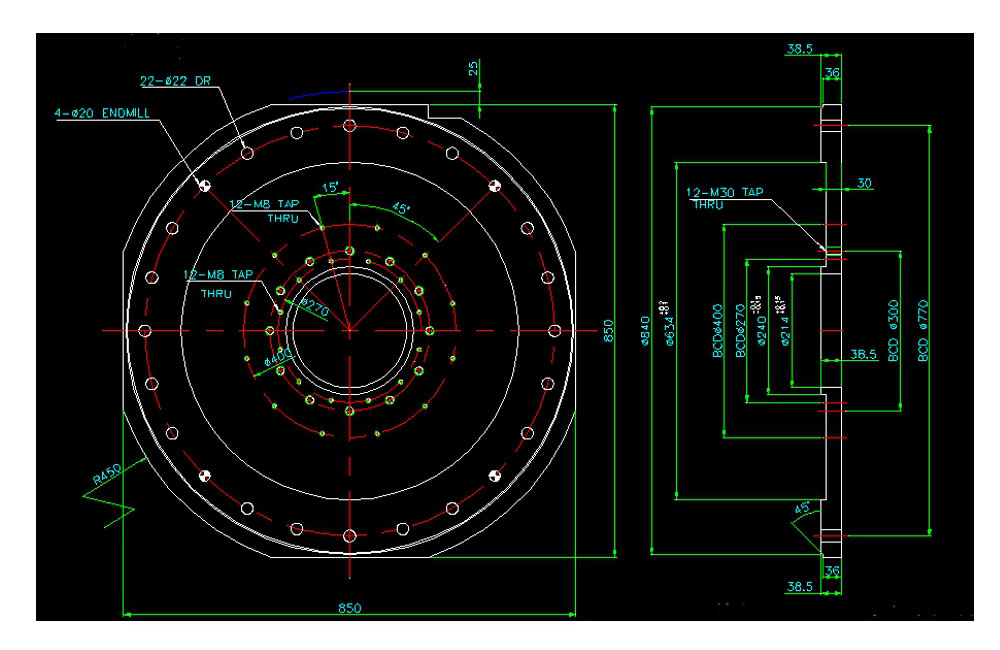

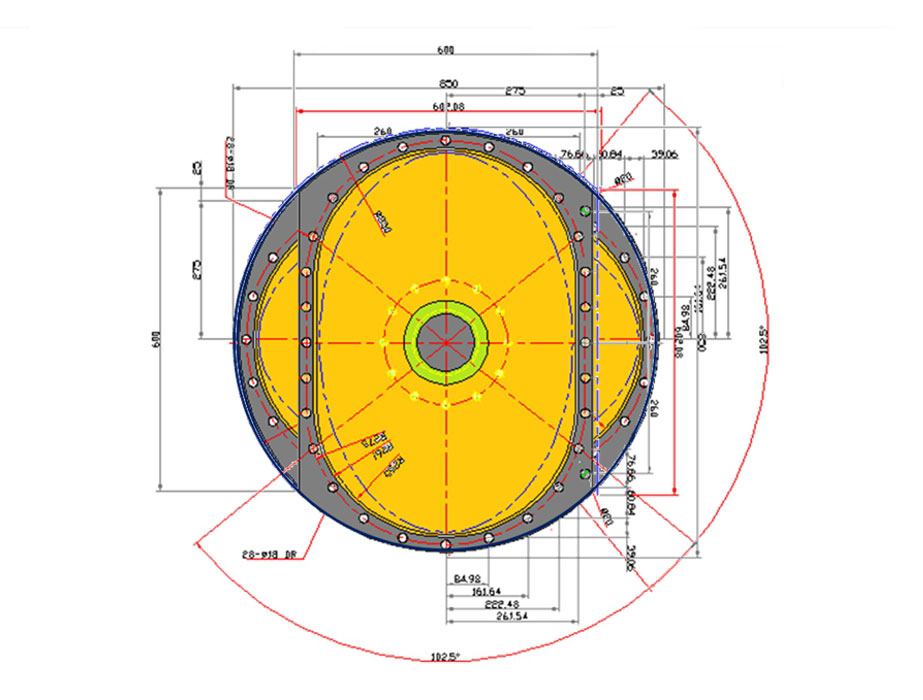

- Square board index hall wheel turbine

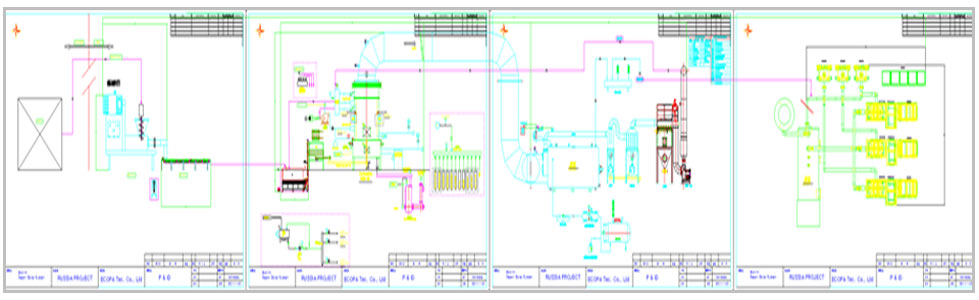

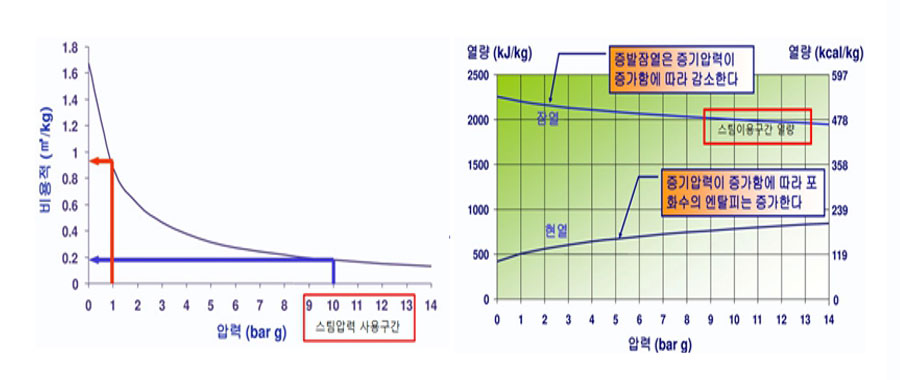

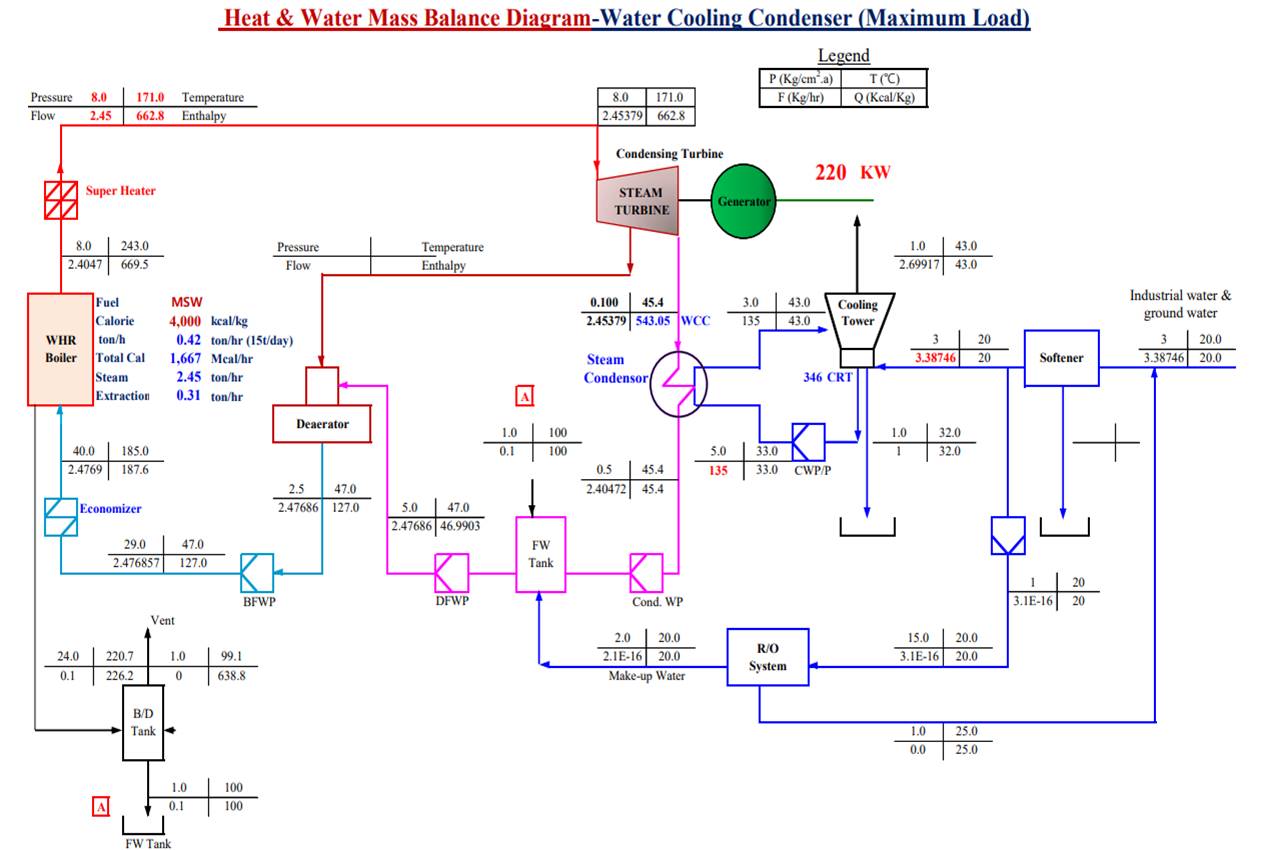

- Low temperature, low pressure, general industrial saturated steam

- An innovative technology turbine power generation system that generates steam pressure of 170-200℃ 7bar-15bar

Characteristics

- Currently, steam turbine power generation is a special steam boiler with high temperature and high pressure

- Steam temperature 250-500°C Steam pressure 20-450 kg/cm2 Ultra high pressure High temperature steam is put into the turbines

- RPM 5,000-12,000 How to turn the generator around with rotational force

- Core power generation facilities or steam turbine to the motor

Industrial saturated steam

Special steam boiler

Generator rotation

Steam motor

Steam turbine power generation

Index hole turbine wheel

Innovative technology turbine system

High temperature, high pressure, steam boiler

Power generation core equipment

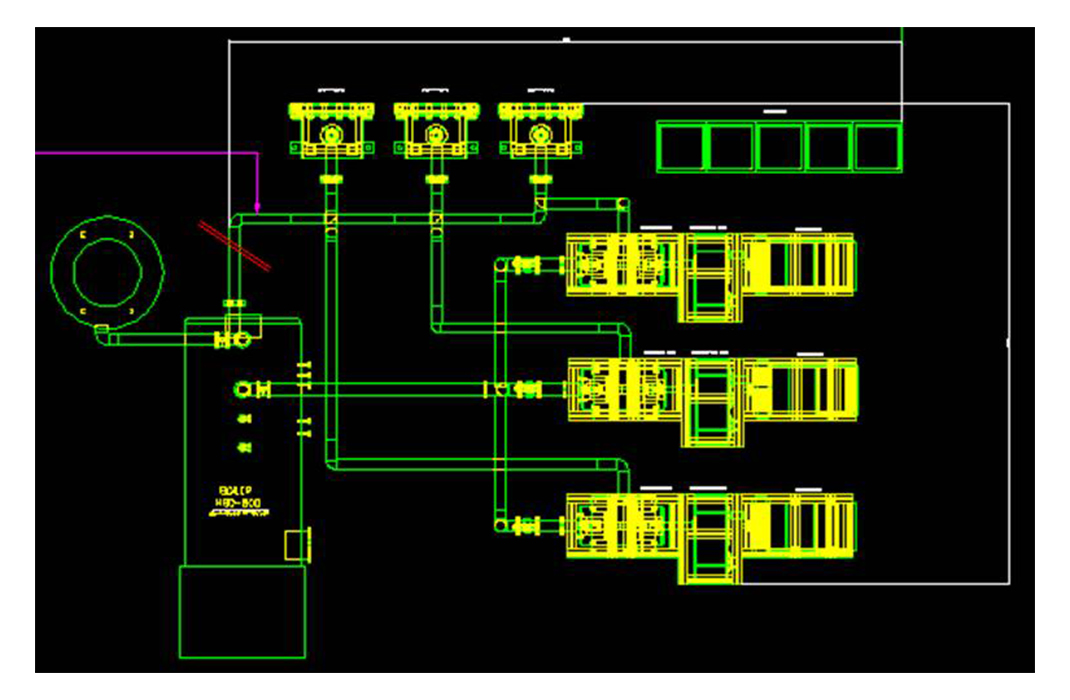

Square board index hall wheel turbine

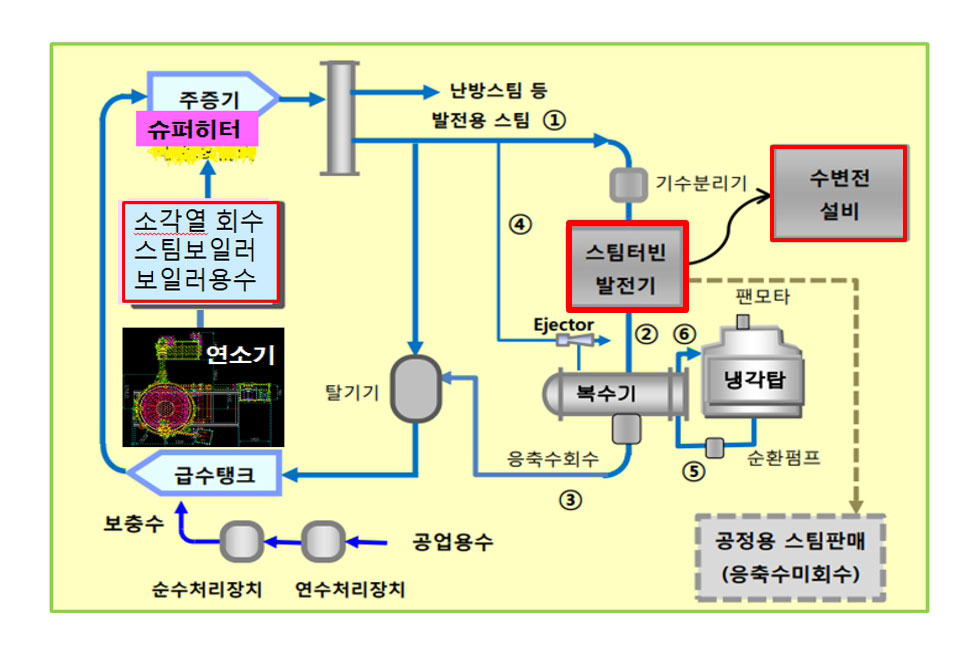

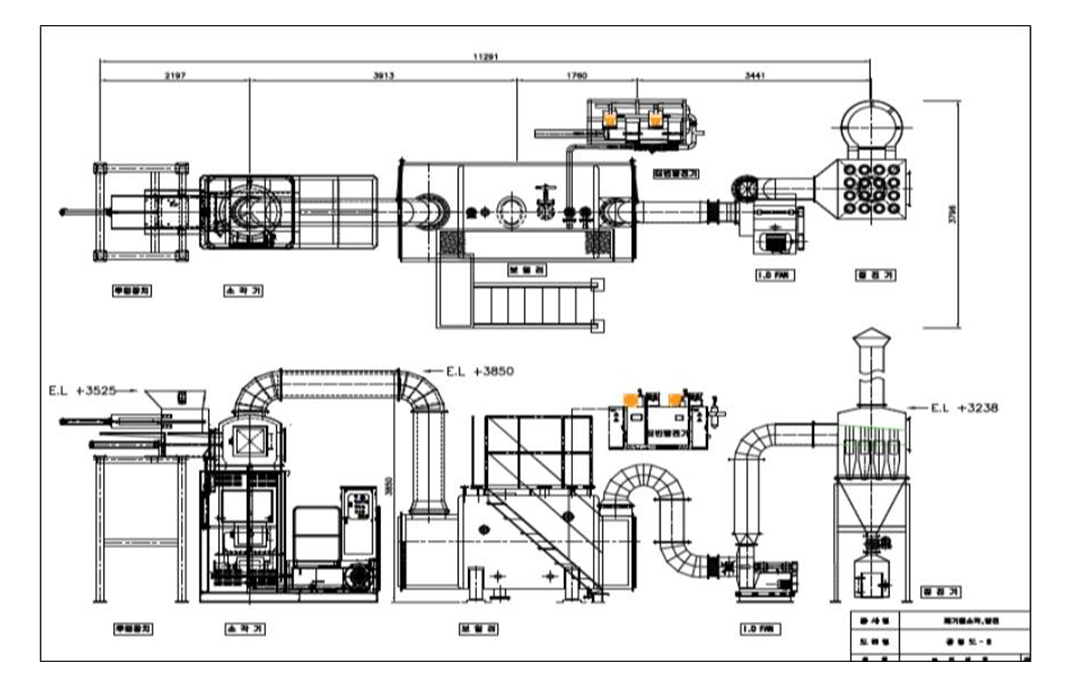

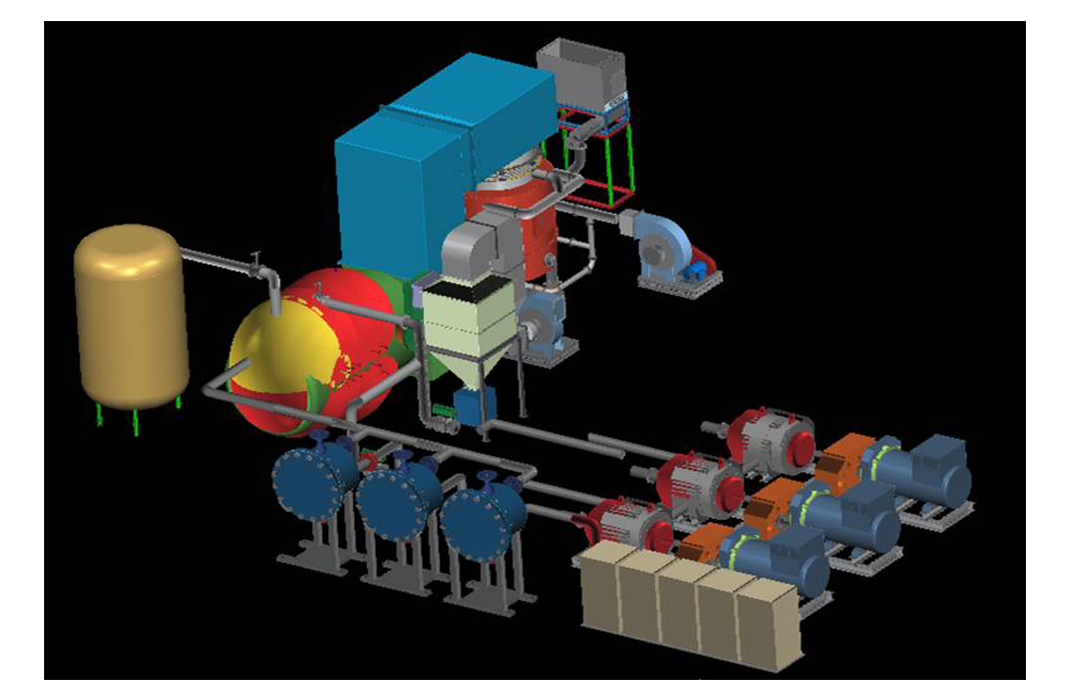

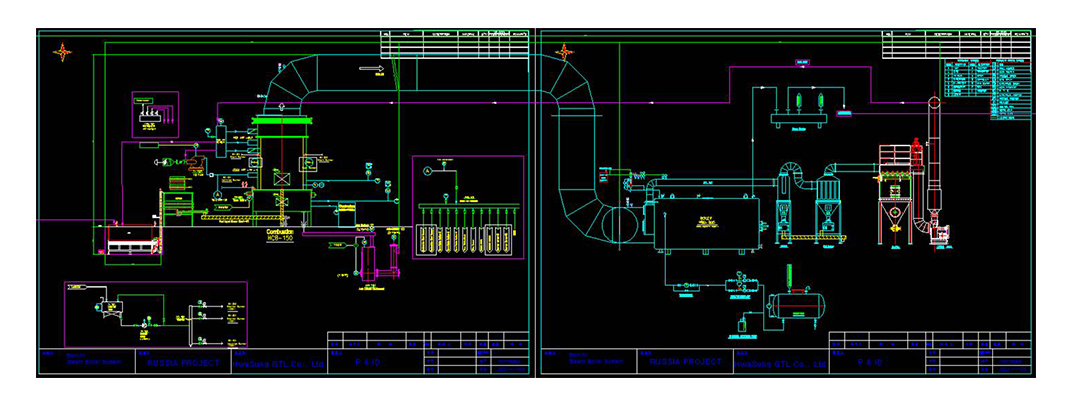

Innovative technology for the development of solid fuel combustion steam boilers

- Development of turbine technology to recycle waste heat energy after operating a power plant turbine using superheated steam, innovative turbine power generation technology to generate power using low-temperature and low-pressure steam produced by general industrial steam boilers, and low-temperature and low-efficiency volumetric turbine technology with low torque

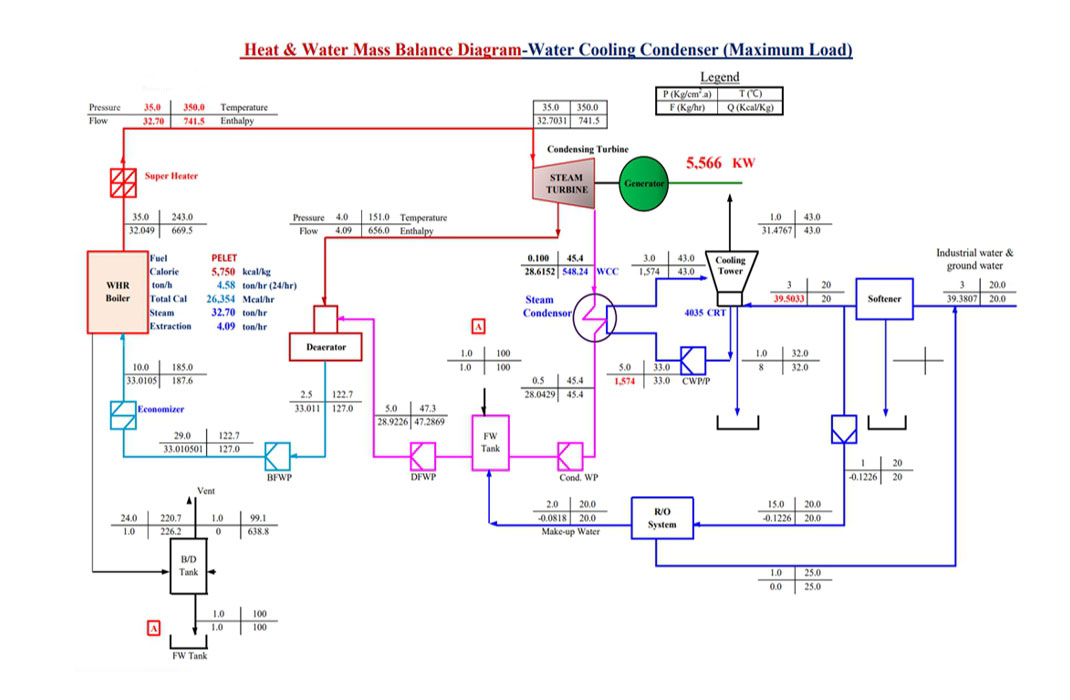

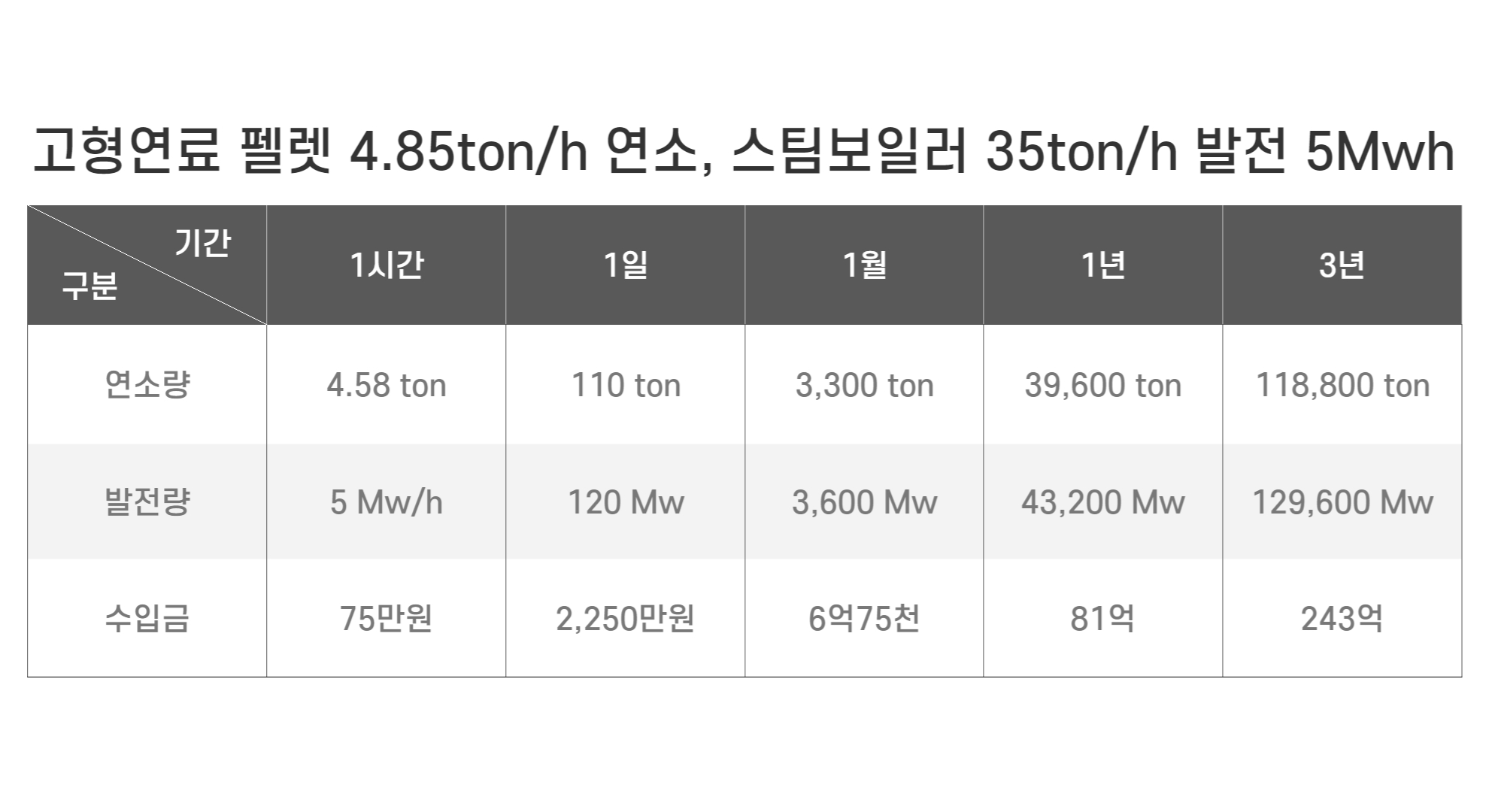

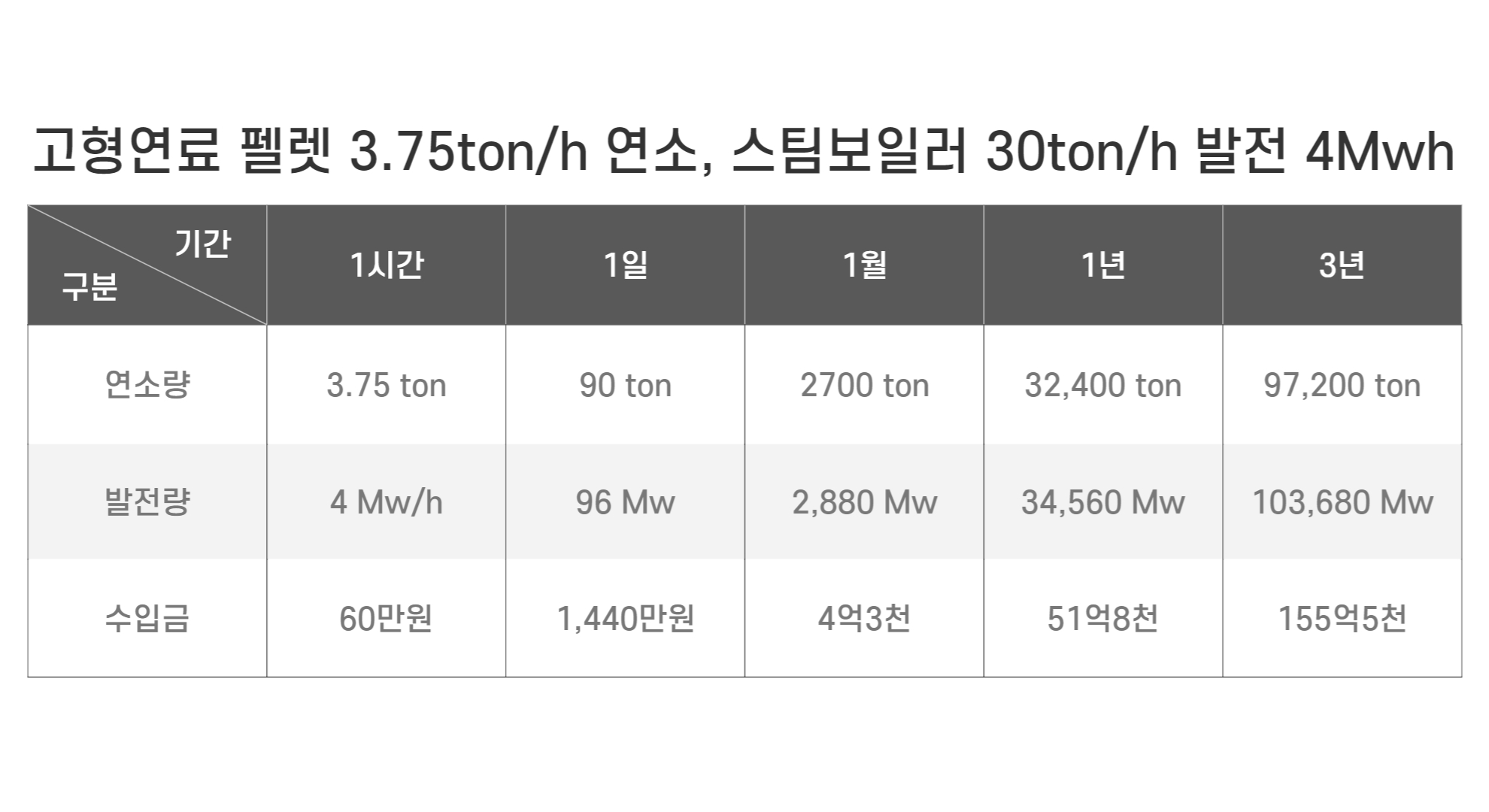

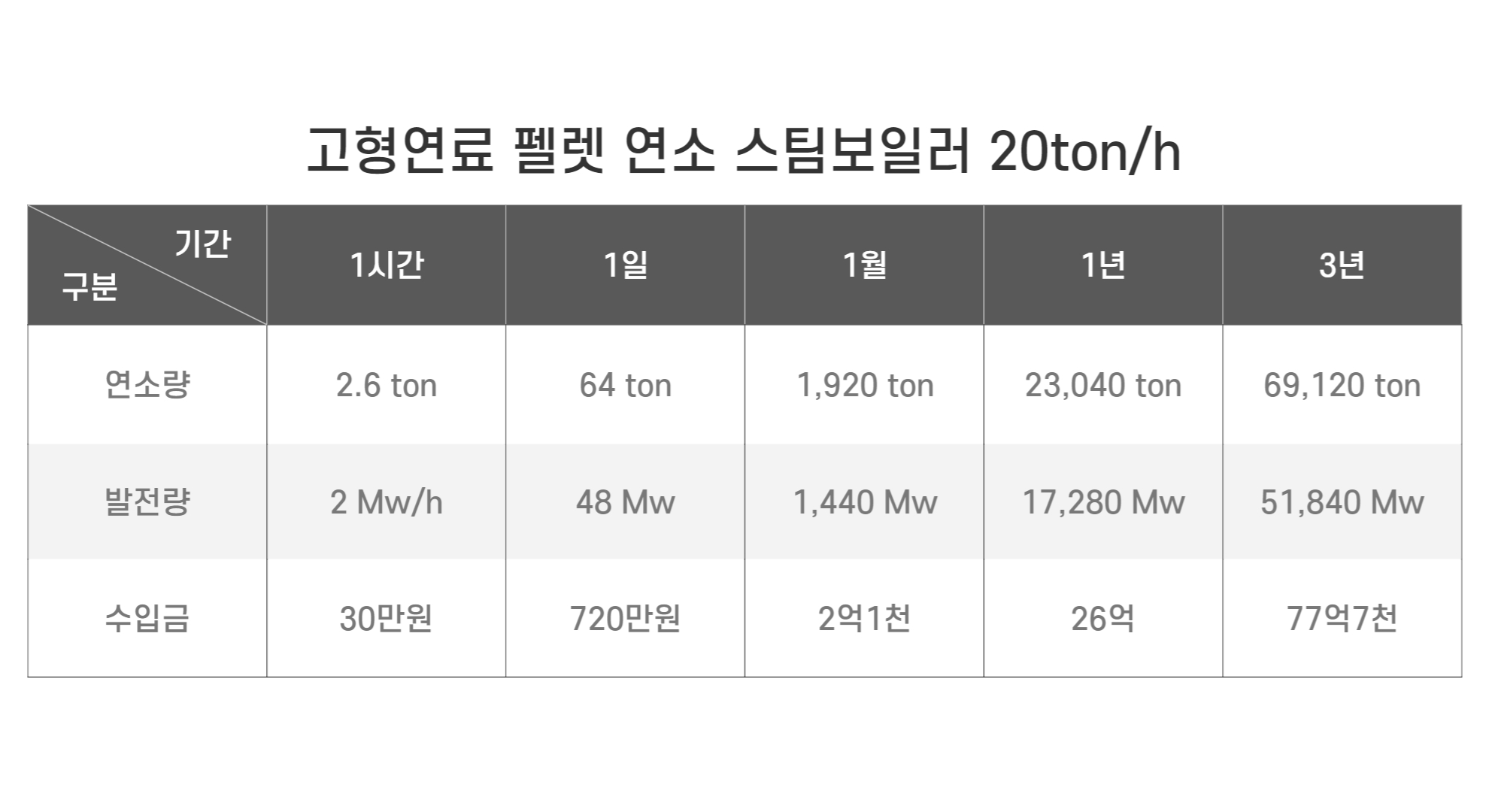

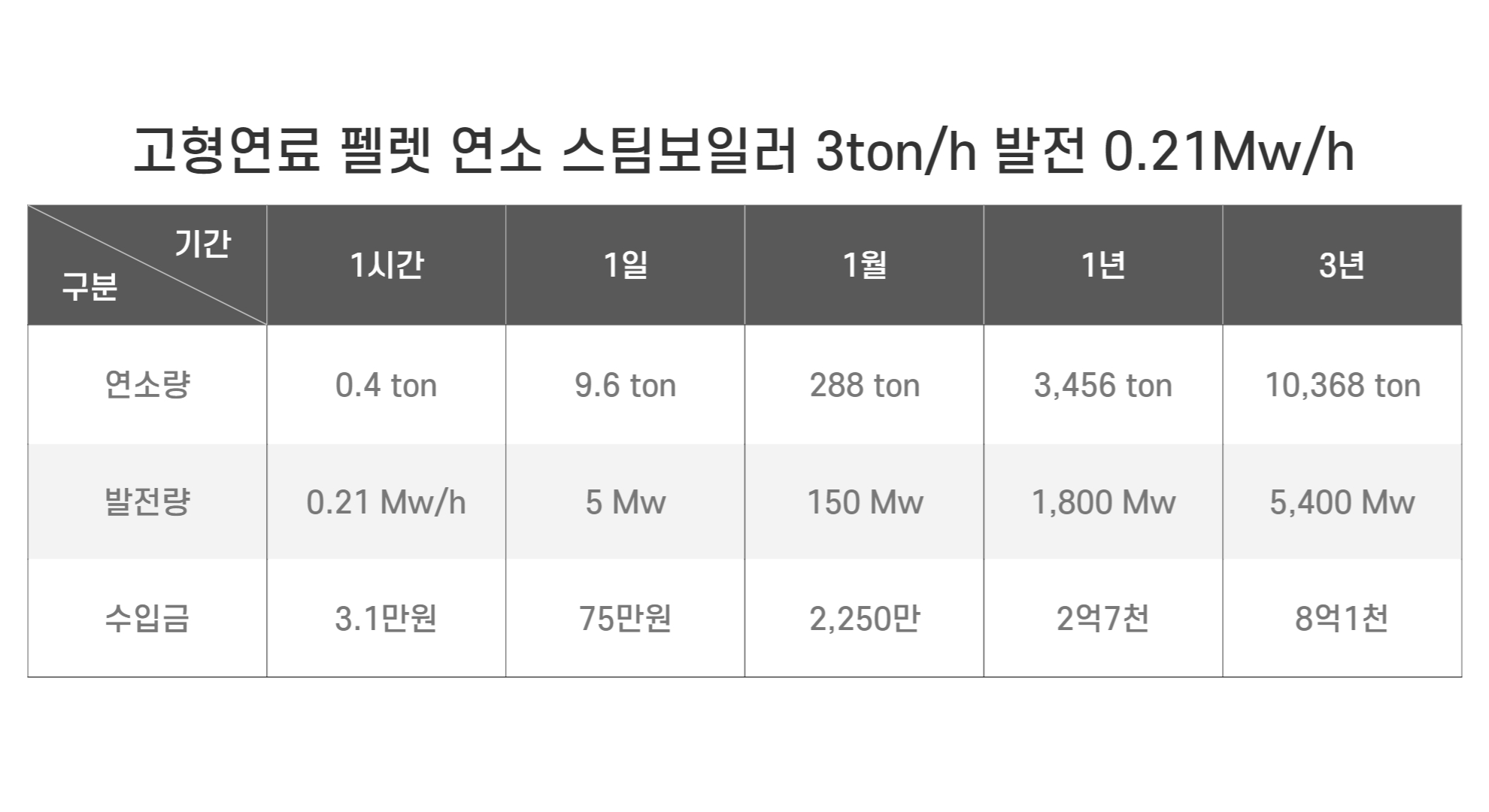

Calculation of the production volume and calorific value of dried solid fuel pellets after the hydrothermal reaction of industrial waste

- Production yield of dried pellets after treating 100 tons of household waste per day (calculated by fixing it to the production yield of 70 tons of pellets)

- Production yield of 70 tons per day (calculation in the case of combustion power generation of 20 tons-35 tons per hour)

- 1kg calorific value based on calorific value 5,725 kcal (above uniform conditions)

- Calculation of total calorific value 70 tons X 1000 kg X 4,500 kcal = 315,000,000 kcal

- Calculation of calorific value per hour 64ton 288,000,000 kcal / 24h = 12,000,000,000 kcal

- Calculation of fuel volume per hour 12,000,000 kcal / 4,500 kcal = 2,666 kg

- Solid combustion steam boiler capacity calculation 2,666 kg/h X 4,500 kcal/600,000 kcal = 19.995 ton/h

- Solid fuel combustion steam boiler design capacity 20-22 tons

- Calculation of power output 20 tons X 600,000 kcal = 12,000,000 kcal/14.35%/860 calories = 2,000 kwh

- Calculation of power generation capacity per day 2,000kwh X 24h = 48Mw/d daily profit of 7.2 million won

- One-month electricity import calculation 48Mw/d X 1,000 X 30d X kw 150 won = 2161, 2.6 billion won in revenue

- Distributed parallel steam boilers with less than 1,000 kwh are advantageous in configuring an optimal power generation system with elasticity ①Two 1/2 boilers ②Installation of 2 sets of 1/2 capacity of turbine power generation system is very advantageous ③Power can be produced at least 50% year-round without full suspension Maintaining the amount of production revenue ④80% load active response, 70% and 50% possible (reasonable production operation without waste of fuel) ⑤Overcoming crisis in case of emergency and securing facility cost economical⑥Reduce A/S maintenance costs and ensure convenience

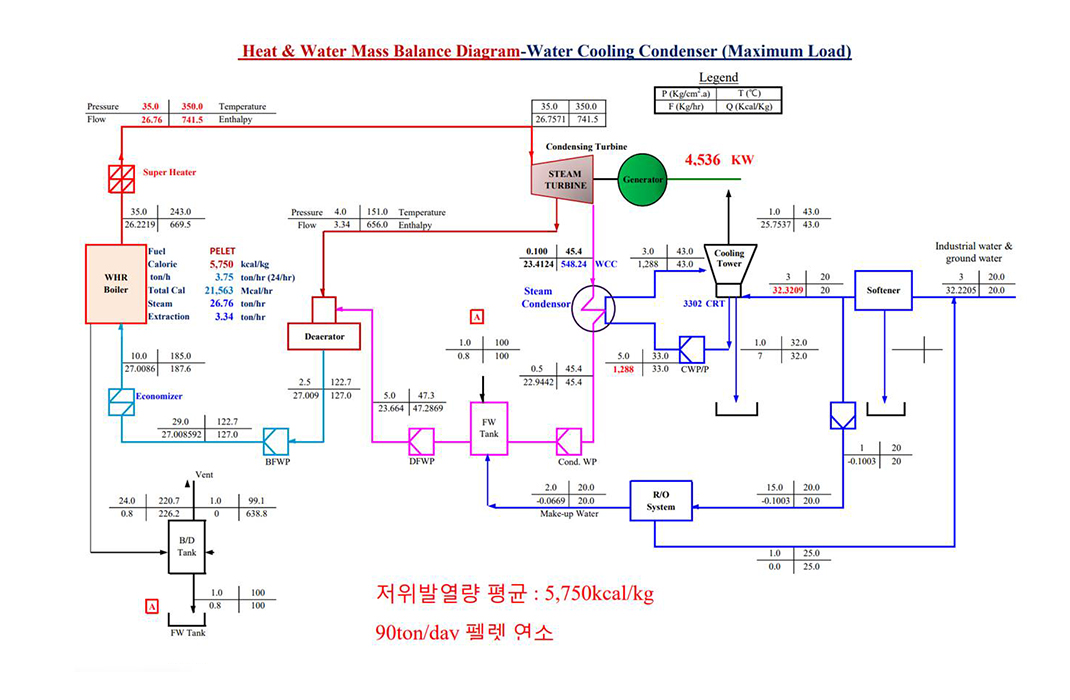

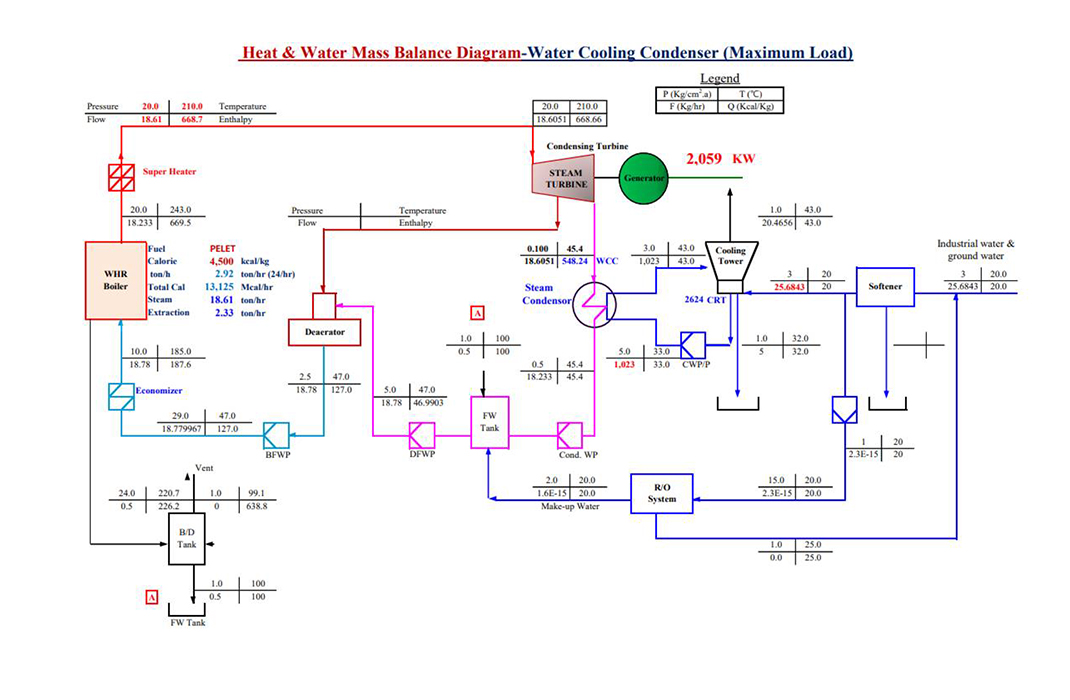

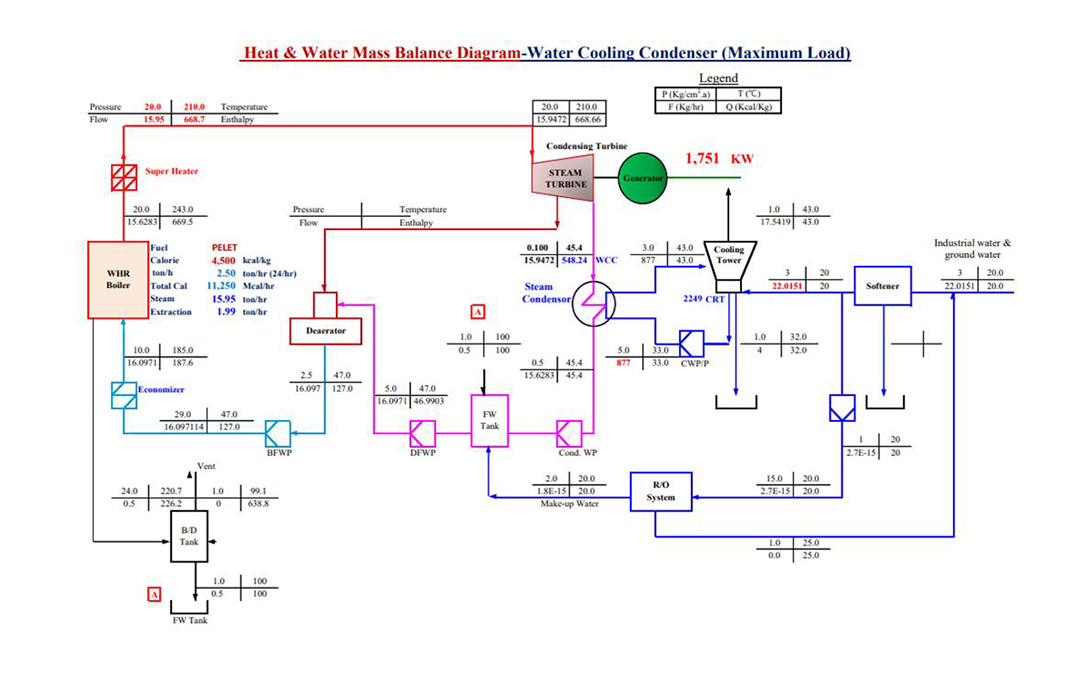

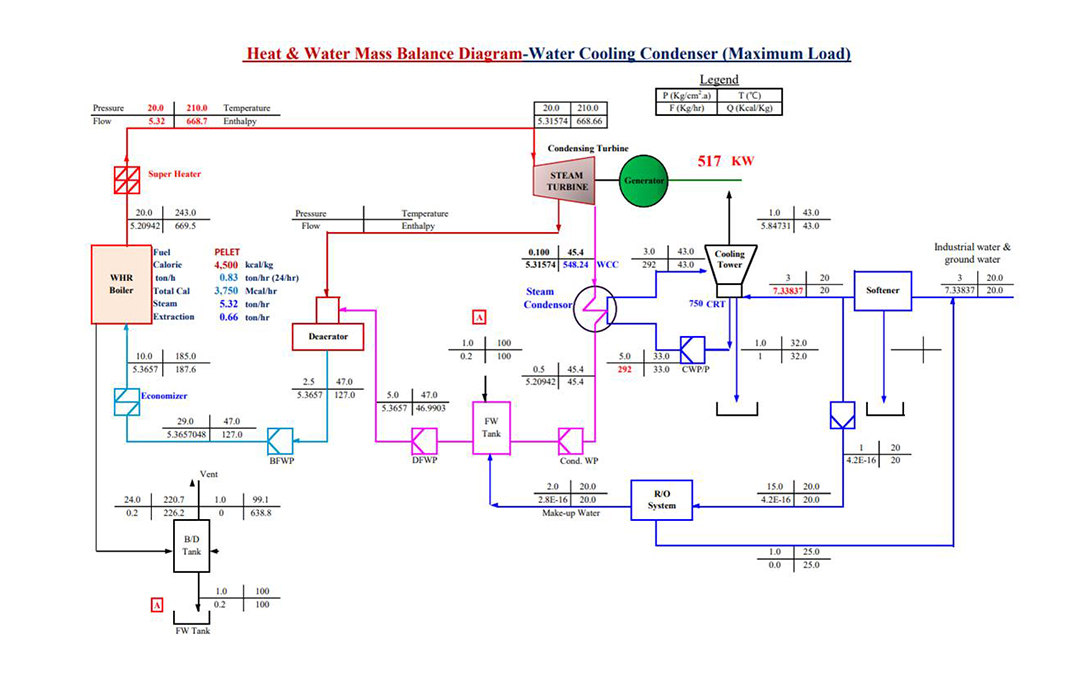

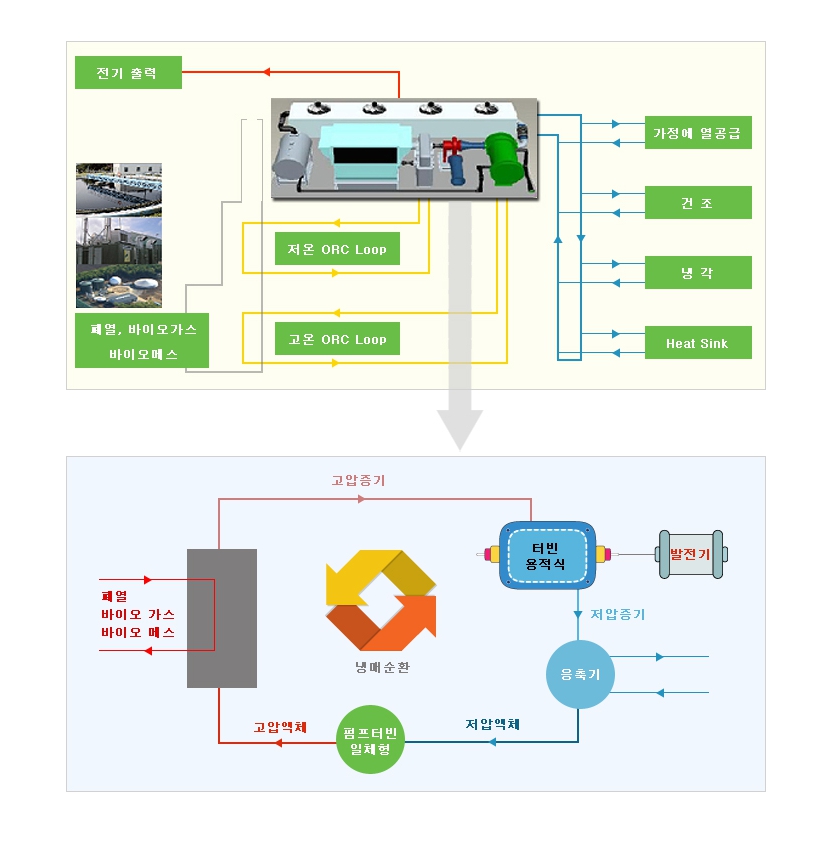

Overview and Benefits of Solid Fuel Pellet Low Temperature and Low Pressure Steam Turbine Power Generation System

- Used fuel waste hydrothermal treatment dried pellet calorific value 4,500KCAL (above uniform calorific value combustion standard)

- Steam temperature 170-210℃, 300-350℃

- Steam pressure 7-15 bar

- Steam pressure 0-1 bar temperature below 100℃ after use

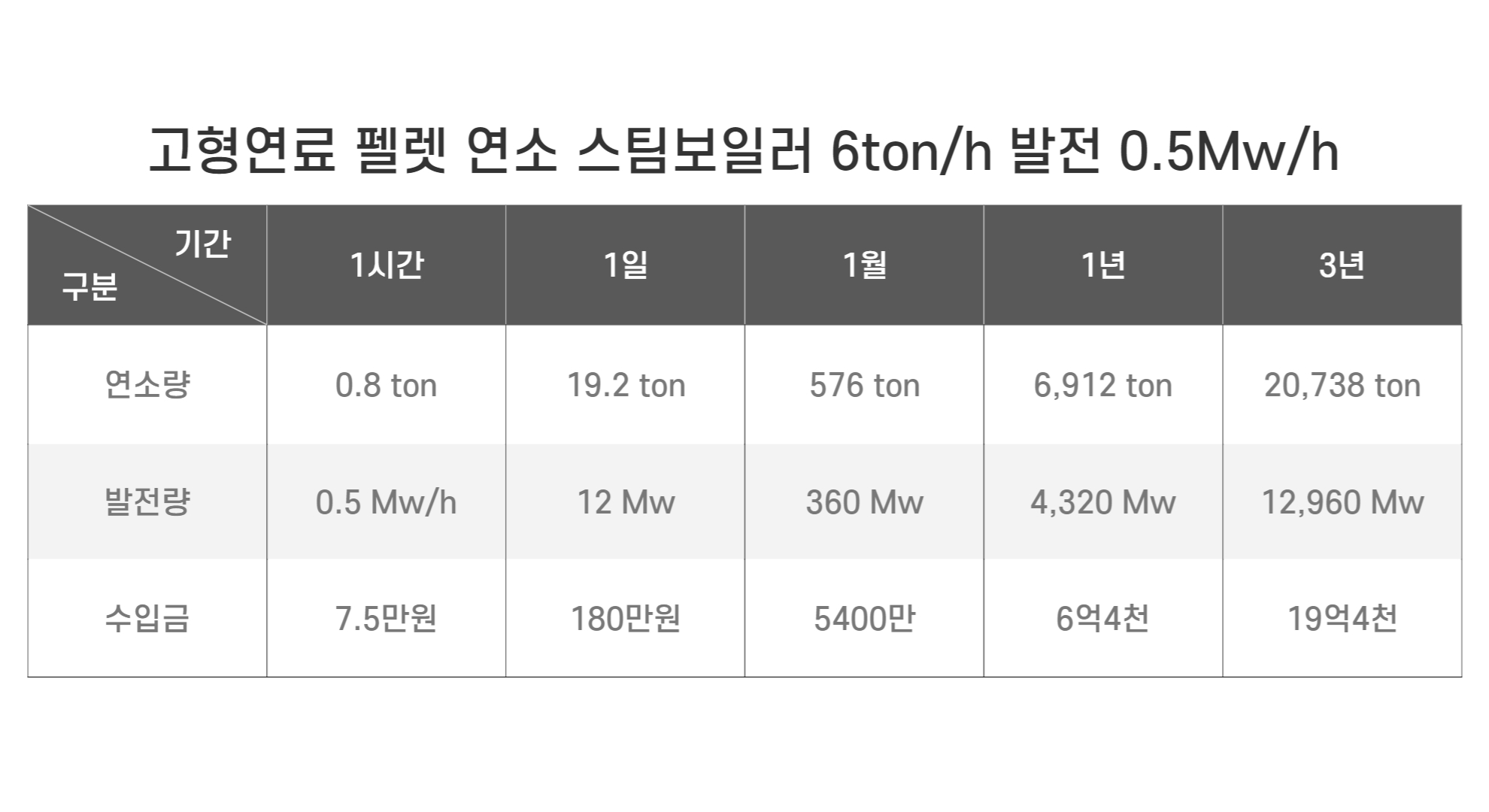

- Special turbine power generation range - Turbine capacity 200 kwh (boiler capacity 3 tons 1,800,000 kcal) 500 kwh (boiler 2,400,000 kcal)

- Power generation by special volume turbine power generation system with general saturated steam temperature and pressure

- The power generation capacity can be generated by Mwh/h in proportion to the boiler steam output

- Advantages of low-temperature and low-pressure steam generation

①Reduce power generation facility costs by at least 30% as high-temperature, high-pressure steam boilers are not required ②Low steam temperature and pressure reduce waste steam condensation multiple costs by 30% or more ③Volume turbine structure Turbine torque is excellent and power generation efficiency is relatively high ④Turbine, generator low speed rotating structure has excellent durability ⑤10-200kwh 500kwh 1,000kwh 2,000kwh Facility Capacity Parallel Distributed Installation Development Organic Response Effect ⑥In the case of A/S maintenance, there is no situation where partial repairable power production is interrupted

Key technologies and differentiation strategies

- As can be seen from the current status of competitors and competitors and domestic and international patents, there are patents that apply the organic Rankine cycle system to generators in various fields, but most turbines are centrifugal turbo turbines.

- The volumetric expansion turbine reduces the amount of fluid vipes (loss) by 1/100mm precision processing to less than 10%, adopting a two-stage turbine method using our world's best patent, triple trochoidal rotor, and applying the fruit medium R-245 to clearly differentiate itself from existing competitive technologies and patents.

The differentiation of technology

- Currently, ORC-applied turbines employ centrifugal turbines, so high-speed (50.000-100.000 RPM) expensive bearings and special generators are being used to develop volumetric turbines internationally.

technological ripple effect

- [Small volume turbine] Currently, there are scroll screws, etc., but screw turbines are used in large capacities and cannot be used in small quantities due to reduced efficiency. In the case of scrolling, they are used for testing purposes only under 5 kW. Scrolls and screws have limitations in expansion ratio, but this technology is a breakthrough that provides high-efficiency performance with free selection of expansion ratio and two-stage expansion output.

- [Economic of production] In the case of the existing centrifugal type ORC turbine, it is sold at a high price due to processing difficulties and manufacturing cost time. This technology is a low-cost and simple processor that reduces processing time and prevents damage to the turbine when inhaling liquid, which is a defect of the turbine, so it can be used both as liquid and gas. The generator is also freely selected at low speed (1500 rpm).

ORC Turbine

-

- The characteristic of the ORC Turbine technology is that there are two inlet and outlet of fluid, and it can produce high power at low pressure and small flow rates.

- Pressure: Minimum 4 Bar / Maximum 6 Bar

- 500 to 600: Used at RPM, connecting directly to the generator without the need for a reducer

- Application: Steam Sensitive Arm Turbine, 6RC Turbine

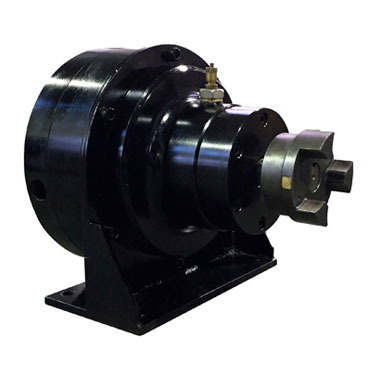

T-101

-

Alpha Turbine Generation has been established in the year of 2015.

But we have been in the field to develop compressor and turbine since 2002.- Item: Compressor Compressor in development

- Configuration: Configuring Gerotor for 2 Stage

- Pressure : 30 Bar

T-102

-

Alpha Turbine Generation has been established in the year of 2015.

But we have been in the field to develop compressor and turbine since 2002.- Item: Steam decompression turbine

- Steam pressure : Min 4 Bar - Max 10 Bar

- RPM : 600

- 15kw:600cc/Rev ㅣ 2kw:840cc/Rev ㅣ 12kw:5L/Rev ㅣ 30kw:13L/Rev ㅣ 50Kw:20L/Rev

T-350

-

Alpha Turbine Generation has been established in the year of 2015.

But we have been in the field to develop compressor and turbine since 2002.- Item: ORC Turbine

- Capacity: 1-50Kw production available

- Expansion ratio: series (7) parallel (3.5)

- Configuration: Configuring Gerotor for 2 stages

Black

-

Alpha Turbine Generation has been established in the year of 2015.

But we have been in the field to develop compressor and turbine since 2002.- 데이식

- Item: Differential pressure turbine

- Use: LPG, CO2, nitrogen, etc

- Expansion ratio : (3.5) parallel series (7).

- Configuration : 2 stage gerotor, a dragon.